The rise of electric vehicles and portable electronics has fueled massive demand for lithium-ion batteries. However, their end-of-life management is becoming a pressing issue. Without effective recycling, discarded batteries can lead to severe environmental harm, resource waste, and safety hazards. A lithium battery recycling machine offers a sustainable solution that maximizes material recovery while minimizing ecological impact.

Stay with us to explore how this advanced system transforms waste into reusable resources and why choosing Tianyicheng is your best investment in green technology.

Table des matières

Lithium-Ion Battery Recycling System Applications

A lithium battery recycling machine is not a single device but an integrated system used across various industries. It is designed to process lithium-ion batteries from sources like electric vehicles (EVs), energy storage systems, consumer electronics, and industrial backup power units. As global demand for lithium grows, so does the importance of efficient recycling to close the material loop.

In electric vehicle manufacturing, recycling plays a critical role in reclaiming valuable metals such as lithium, cobalt, nickel, and copper. These elements are finite and expensive to extract from natural resources. By utilizing a lithium battery recycling system, manufacturers can reduce dependency on mining and stabilize raw material costs. Moreover, it helps companies comply with global sustainability regulations such as the EU Battery Directive and China’s dual-carbon goals.

For consumer electronics, the recycling system handles small-format batteries from mobile phones, laptops, and power tools. It efficiently separates components like aluminum foil, copper foil, and active materials (cathode and anode powders). This recovered material can be reused in new batteries or other industrial applications, reducing electronic waste dramatically.

In short, lithium battery recycling machines serve a cross-sector purpose: they enable a circular economy by recovering high-value metals, conserving resources, and ensuring environmental safety.

Comprehensive Battery Recycling Solutions

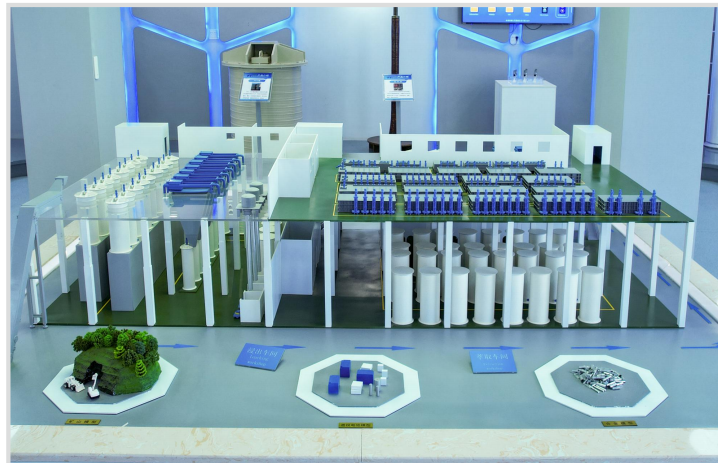

Modern battery recycling machines offer a fully automated, closed-loop solution that integrates physical and chemical separation technologies. These systems are engineered for flexibility, allowing operators to process various types of lithium batteries—including cylindrical, prismatic, and pouch cells—without compromising efficiency.

A comprehensive recycling line generally includes several key modules:

-

Discharge and dismantling units to safely neutralize battery charge and separate casings.

-

Crushing and shredding systems that break down cells into smaller particles.

-

Separation units for sieving, magnetic sorting, and airflow classification to isolate materials such as aluminum, copper, and black powder.

-

Chemical leaching and purification stages that extract lithium, nickel, and cobalt for reuse.

With a fully enclosed and dust-free design, modern systems meet strict environmental protection standards. Automated temperature control and explosion-proof technologies ensure safe operation during every stage of the process. Tianyicheng’s integrated solution, for instance, includes smart control software that monitors real-time parameters like current, pressure, and yield rate.

Beyond material recovery, these machines reduce waste disposal costs and carbon emissions. By turning used batteries into valuable resources, businesses not only comply with sustainability standards but also gain significant financial and reputational advantages.

Waste Lithium-Ion Battery Recycling Process

Les waste lithium-ion battery recycling process involves multiple carefully controlled steps to extract valuable metals and neutralize hazardous substances. It typically includes the following stages:

-

Battery Discharge: Used lithium-ion batteries are first fully discharged to eliminate electrical risks during handling. This is achieved using conductive solutions or controlled short-circuit systems.

-

Manual Dismantling: Large battery modules, such as EV packs, are dismantled into smaller cells. Plastic, steel, and aluminum shells are separated for independent recycling.

-

Crushing and Sorting: Batteries are shredded under inert or vacuum conditions to prevent oxidation or explosion. The crushed materials are passed through sieves and magnetic separators to isolate metallic fractions.

-

Thermal Treatment or Pyrolysis: This stage removes organic binders and electrolyte residues, making the material suitable for further chemical extraction.

-

Hydrometallurgical Process: Chemical leaching is used to extract metals such as lithium, cobalt, nickel, and manganese from the active material (commonly known as “black mass”).

-

Purification and Precipitation: Recovered elements are purified through solvent extraction or ion exchange to produce high-purity salts or oxides used in new batteries.

This recycling workflow not only maximizes recovery rates—often exceeding 95% for cobalt and nickel—but also ensures minimal environmental pollution. Advanced systems, such as those by Tianyicheng, adopt closed-loop water circulation and gas filtration to achieve zero emissions during operation.

Through these sophisticated processes, the lithium battery recycling machine enables sustainable management of critical materials, reducing both resource depletion and landfill waste.

How Our Battery Recycling Equipment Operates

Tianyicheng’s lithium battery recycling equipment is designed for efficiency, automation, and safety. The system is modular, allowing flexible capacity expansion according to client needs—from small laboratory setups to industrial-scale recycling plants.

Step 1: Feeding and Preprocessing

Used batteries are loaded into an automated feeding system. A discharge and sorting module ensures safe handling, segregating lithium-ion types from other chemistries.

Step 2: Crushing and Separation

The batteries are shredded in a sealed, temperature-controlled chamber. Through magnetic and airflow separation, ferrous materials, copper foil, aluminum foil, and black mass are efficiently divided.

Step 3: Chemical Recovery

The black mass undergoes hydrometallurgical treatment. Using proprietary chemical formulations, lithium, cobalt, and nickel are dissolved, purified, and re-crystallized into high-purity compounds such as Li2CO3 and CoSO4.

Step 4: Waste Treatment and Recycling

All process water is filtered and reused in a closed cycle, while gas and dust are captured via multi-stage filtration. Solid residues are treated for safe disposal or reprocessing.

The system runs on PLC and SCADA-based control architecture, providing full automation, remote monitoring, and error diagnostics. Operators can adjust process parameters and track production yield via digital dashboards, ensuring consistent and traceable performance.

In summary, Tianyicheng’s recycling machine delivers precise material recovery with minimal environmental footprint—combining engineering innovation with eco-responsibility.

Unique Advantages of Tianyicheng Battery Recycling

Hangzhou Tianyicheng New Energy Technology Co. Ltd. stands out as a global leader in lithium battery recycling machine manufacturing. The company integrates R&D, production, and technical services, providing one-stop recycling solutions tailored to various industrial needs.

Here are the core advantages that make Tianyicheng unique:

-

High Recovery Rate: Proprietary technology ensures metal recovery rates exceeding 98% for cobalt and nickel, and 90% for lithium—outperforming most conventional systems.

-

Automation and Safety: Advanced sensors and AI-based monitoring reduce manual intervention and eliminate explosion or leakage risks.

-

Eco-Friendly Design: Closed-loop water and air systems meet stringent environmental standards (ISO14001 and CE-certified).

-

Custom Engineering: The recycling line can be customized according to capacity, battery type, or local regulations, ensuring optimal performance for each client.

-

Comprehensive After-Sales Support: Tianyicheng provides installation, training, remote diagnostics, and long-term maintenance, helping clients achieve stable production from day one.

-

Global Expertise: With successful projects across Asia, Europe, and the Middle East, the company has accumulated valuable experience in handling regional compliance and logistics.

By integrating green innovation with industrial practicality, Tianyicheng empowers manufacturers and recyclers to achieve true circular economy goals while maintaining profitability.

Industries We Serve

Tianyicheng’s battery recycling machines are used across multiple sectors where lithium-ion batteries dominate:

-

Electric Vehicles (EVs): As EV adoption surges, battery recycling becomes essential for recovering valuable metals and reducing the carbon footprint of battery manufacturing.

-

Energy Storage Systems: Renewable energy storage projects rely on large-scale lithium-ion batteries that eventually require recycling for safe material reuse.

-

Consumer Electronics: Smartphones, laptops, and wearables generate significant battery waste that can be efficiently processed using small-scale recycling units.

-

Industrial Equipment: Forklifts, UPS systems, and solar backup installations also depend on rechargeable lithium batteries that need end-of-life treatment.

-

Research and Pilot Plants: Laboratories and technology developers use compact recycling systems to test material recovery processes before scaling up.

In every industry, Tianyicheng provides a customized lithium battery recycling solution—from process design to full-scale installation—ensuring compliance with environmental laws and maximizing the client’s return on investment.

Résumé

Les lithium battery recycling machine is a cornerstone of sustainable energy infrastructure. By recovering valuable metals and minimizing waste, Tianyicheng’s advanced recycling technology leads the way toward a greener, circular economy for the battery industry.