Plastic polypropylene plate is one of the most commonly used and versatile thermoplastics available. It is a low density, stress-resistant polymer and can be shaped by injection moulding or extrusion methods.

Polypropylene is a homopolymer and copolymer that offers excellent chemical, corrosion, and stain resistance. It is also resistant to high pressure and heat. This makes it a common material for industrial applications that have to withstand intense abrasion and wear, including slings, straps, and other parts of equipment.

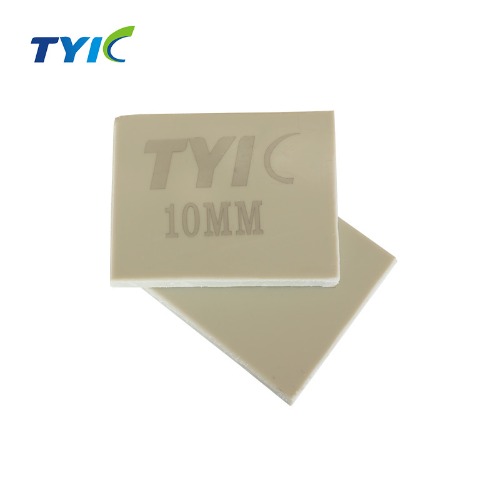

PP can be manufactured in a variety of thicknesses and can be filled with aramid, carbon, glass powder, or metal fillers. These fillers can be used to increase the strength of polypropylene or to improve its thermal, electrical, and optical properties.

This plastic is commonly used in packaging and reusable food containers. It has excellent flexural and torsional strength, making it ideal for containers that will be manipulated and bent frequently.

The melting point is high, which means PP can withstand a variety of temperatures, and it is also a good electrical insulator. This allows it to be used in applications such as hot beverage cups and yogurt containers.

Due to its semi-crystalline nature, polypropylene can be easily molded and has a low melt viscosity (easy flow). This, together with its pseudoplastic nature, leads to very fast injection rates and a low shear rate (fast filling).

It is a good choice for hinges, bottle tops, and other elements that need to withstand high amounts of twisting and rotation without snapping. It is also a popular material for laboratory items, such as labware closures and Petri dishes.