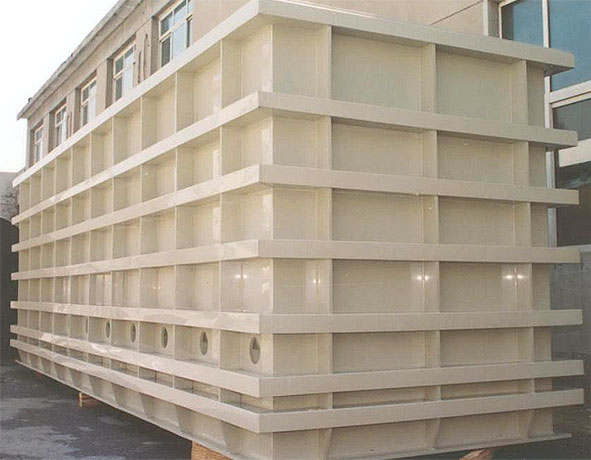

Polypropylene Storage Tank

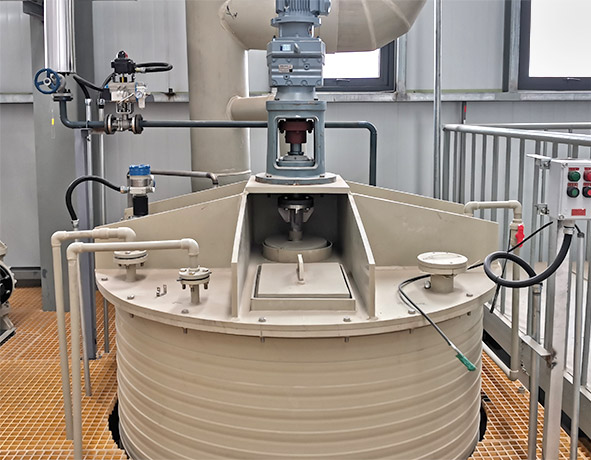

PPH, HDPE spiral wound storage tank products mainly use polypropylene and high-density polyethylene plastic anti-corrosion equipment produced by expanded winding without welding seam technology, various specifications of tanks, tanks, various towers and pipelines. In the production process, the product from the main body to the accessories is completely processed from a single material of the same kind, but it still has the characteristics of non-leakage and weldability. Its price is much lower than that of stainless steel products. It can be passed under natural conditions. The product has an excellent reputation for ownership in various fields.

The company has achieved good performance in many fields such as chemical industry, steel, metallurgy, pharmacy, papermaking, electric power, food, water treatment, etc., and has been well received by the majority of users.

English

English Español

Español