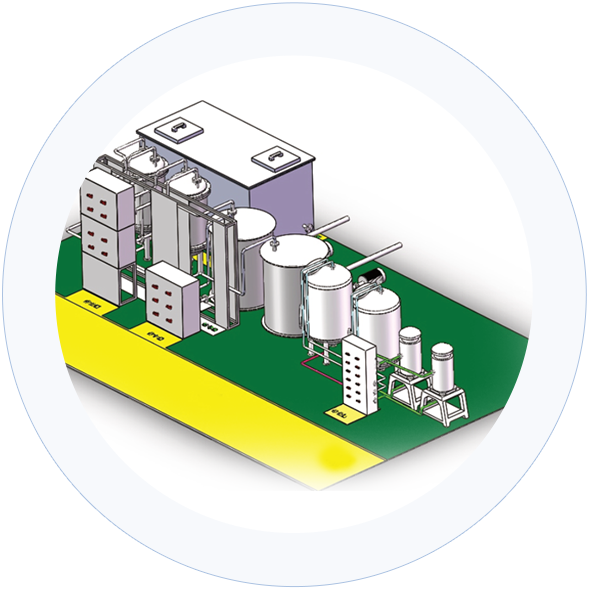

The micro-interface oil removal system is a high-efficiency oil removal equipment developed by the company. It is a complete set of equipment for removing organic oil in the extraction solution during the non-ferrous metal wet smelting process. The oil removal effect reaches 1ppm.

The micro interface oil removal device makes use of the different wetting angle and surface tension of water and oil on the micro surface of the selected special material, so that the tiny oil particles can separate from the surface of the material and float up after growing up, so as to achieve the purpose of separation. The modified fiber material is used to remove oil, which has the characteristics of large specific surface area, high surface energy, strong demulsification effect, lipophilic and hydrophobic.

Before degreasing

Constant current treatment room

Micro interface degreaser

High efficiency separator

Transfer tank

Activated carbon filter

Oil reservoir after oil removal

Precision filter

The surface energy of the modified fiber is strong, and it has a strong demulsification effect on the emulsified oil drops. It has the function of lipophilic and hydrophobic, and can gather small oil drops into large oil drops, making the solution easier to separate oil and water. The oil removal efficiency can reach below 10ppm.

The fiber is 2-3um ultra-fine wire shape, which has a large specific surface area, which is 1000 times of the same 2-3mm spherical, and the oil removal efficiency is greatly improved.

Micro interface oil removal is mainly used for physical demulsification, which does not participate in chemical reaction and does not occupy the organic phase, so the organic phase can be recovered and reused with high economic benefit.

The micro interface oil removal equipment has the advantages of automatic operation, simple operation and reliable operation without adding auxiliary materials.

The oil content of the solution is less than 10ppm, and most of the macromolecular oil has been removed, which improves the utilization rate of activated carbon and reduces the consumption.

Micro interface oil removal device is separated by physical method, without any derivatives, and has long service life.

The crystallinity and molecular orientation characteristics of PVC industrial grey sheet are key factors that influence its mechanical, thermal, and processing properties: Crystall...

read moreThe materials used in the construction of chemical storage tanks are selected based on the type of chemicals being stored, the operating environment, and regulatory requirements. H...

read moreControlling and optimizing the mixing intensity in a mixer-settler is crucial for enhancing the efficiency of the liquid-liquid extraction process. The right level of mixing ensure...

read morePoor phase disengagement in a mixer-settler can lead to several operational and process-related issues. Here are some potential problems that can arise: 1. Reduced Separation Effic...

read more