The company is one of the largest domestic manufacturers and enjoys a high reputation. It has provided more than 100 extraction equipment projects for large listed companies such as China Enfi, GEM, Guangxi Yinyi, Tianjin Maolian, and Jinchuan Group. It is the national standard "Cobalt Editor-in-chief of "Smelting Plant Process Design Specification".

It adopts extruded all-plastic A-board or laminated all-plastic A-board, processed in fixed size, reducing the welding ratio; semi-automatic extrusion welding gun imported from Germany, uniform discharge, stable temperature control and good welding quality.

Increase the diversion tube to improve the mixing effect and suction; optimize the baffle to reduce the centrifugal separation in the mixing chamber; the labyrinth water seal reduces the volatilization of gas and improves the operation.

Low-speed operation can meet the requirements of mixing and suction, reducing gas dissolution. Adopting the company's patented product-laminated glass fiber reinforced plastic integrated mixing paddle, excellent corrosion resistance, dynamic balance and rigid strength.

From the horn-shaped feed inlet-the baffle-the annular grid-the IMI clarification baffle, to the end gathering plate, gradually increase the clarification rate and reduce the two-phase entrainment. Thread adjustment controls the two phase ratios and the return flow rate, which is easy to operate and has high adjustment accuracy. Install an external plexiglass sight glass for easy observation and long service life.

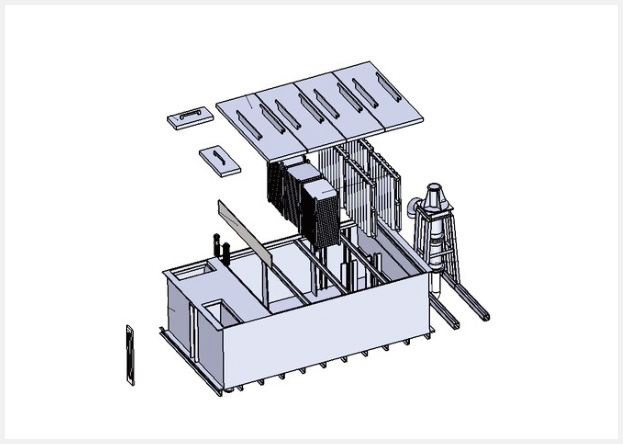

The tube-type mixing extractor independently developed by the company is the first in China, which greatly improves the efficiency of mixing and extraction, reduces investment and operating costs, has excellent operating performance, and has obvious effects.

Less Invesment

Low Operating Cost

Good Environmental Protection Effect

Convenient Operation

Reduce the height and floor space of the workshop. The extractor is small, occupying an area of less than 10, and the height of the transmission device is less than 2m;

The area is reduced, which can increase the production capacity of extraction equipment per unit area, and correspondingly reduce the project investment;

There is no conventional large-scale mixing tank, the extractant and metal aqueous solution for single-stage filling are reduced by 20%, the capital occupied by single-stage filling is correspondingly reduced by 20%, and the total investment is significantly reduced.

Low installed power and low power cost of extraction operation. The installed capacity and operating power of the extraction system with the same capacity are reduced to less than 50% of the conventional extraction mixing tank;

Low investment and operation cost of extraction system. It is also suitable for the transformation and application of the old extraction system;

There are no wear parts in the mixer, and the noise is low. It can run stably for a long time after debugging;

The equipment is reusable, easy to move, move, transport and install to new projects, and has high residual value of equipment assets;

Modular design, simple structure, flexibility to adapt to the extraction system capacity.

The mixer is closed. There is no leakage of acid mist and oil mist, and the site environment is good. Prevent oxidation and volatilization of organic phase. There is no burning space and the fire safety is improved;

Save the investment of oil mist and acid mist absorption system and the cost of waste gas treatment;

There is no volatilization of oil mist in the mixer, which reduces the consumption of extractant and solvent oil;

All the materials used are environment-friendly and can be recycled completely, which is environmentally friendly.

TWhen parking, the oil and water in the mixing chamber will not flow back into the oil tank and water phase tank, resulting in the mutual inclusion and entrainment of oil and water;

In the process of production and operation, with the size of liquid feeding, the liquid pumping volume and liquid level of extraction system can be automatically and dynamically balanced;

The shell and transmission parts are all CPVC. According to different media, 2205 or Hastelloy is used for the main shaft, which has excellent corrosion resistance, long service life, light weight of spare parts and easy replacement.

The crystallinity and molecular orientation characteristics of PVC industrial grey sheet are key factors that influence its mechanical, thermal, and p...

read moreThe materials used in the construction of chemical storage tanks are selected based on the type of chemicals being stored, the operating environment, ...

read moreControlling and optimizing the mixing intensity in a mixer-settler is crucial for enhancing the efficiency of the liquid-liquid extraction process. Th...

read morePoor phase disengagement in a mixer-settler can lead to several operational and process-related issues. Here are some potential problems that can aris...

read more