- Technology Of Material Recycling for Lithium Batteries(Ternary 、LFP 、LCO etc.)

- Nickel-cobalt intermediate product(MHP) recover process

- Rare and precious metal extraction process(Ni\Co\Mn\Li\Cuand other Rare Metals)

- Waste Gas Treatment Process

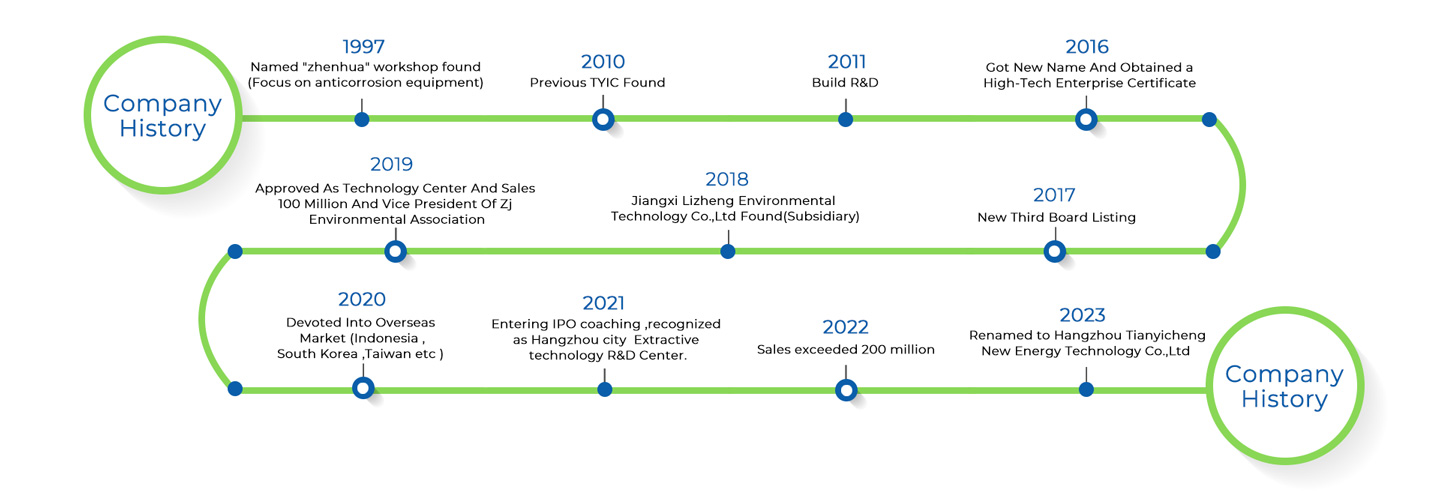

Hangzhou Tianyicheng New Energy Technology Co., Ltd. is a national high-tech enterprise listed on the new third board.

Hangzhou technology center specializes in process design and equipment manufacturing of non-ferrous metals (precious metals such as nickel, cobalt, copper, lithium, manganese and zinc) and rare earth hydrometallurgy.

Its main products include extraction equipment, PPH / HDPE equipment, micro interface degreasing equipment and stirring equipment.

It is a well-known domestic professional manufacturer of extraction equipment and anti-corrosion storage tank. It has a good reputation and influence in the industry.

Based on the material characteristics and the target product, conduct in-depth analysis and process simulation to predict the optimal parameters, avoid trial-and-error costs, and maximize the success rate and economic efficiency in one go. By adopting highly efficient mass transfer and separation technologies, the processing capacity per unit time and separation efficiency are significantly enhanced, while fixed costs are reduced.Integrating technologies such as thermal coupling, solvent recovery, and waste heat utilization, the system systematically reduces the costs of steam, electricity, and solvent consumption, achieving a circular economy.

The company has achieved good performance in many fields such as chemical industry, steel, metallurgy, pharmacy, electric power, mining, etc., and has been well received by the majority of users.

Tianyicheng is committed to providing users with efficient, high-quality, environmentally friendly, and low-cost design and technical solutions. It provides customers with comprehensive high-quality products and services.

Our products are used in various industriesand have been recognized by our customers.