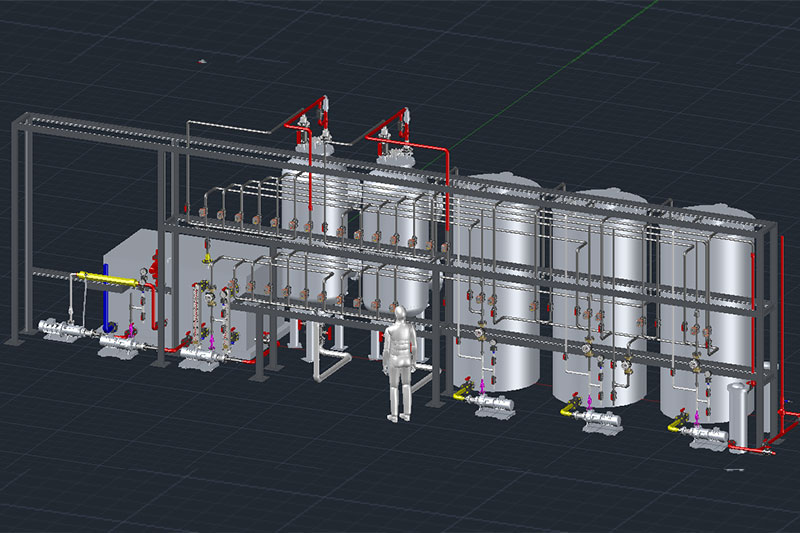

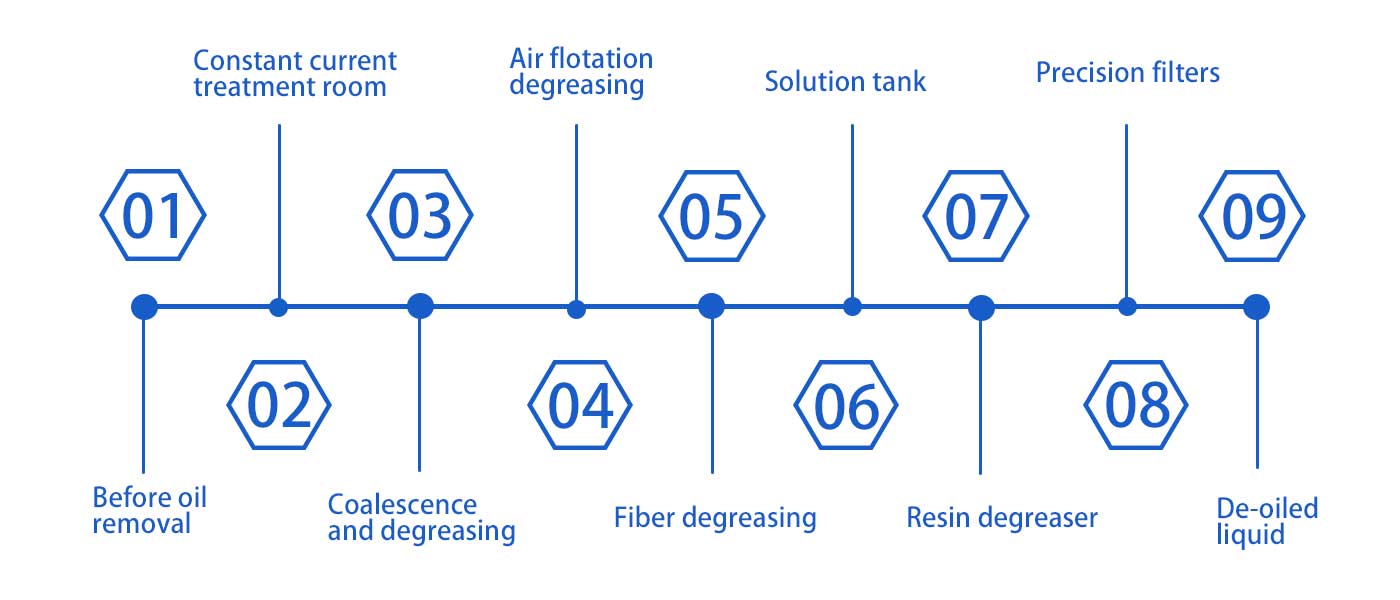

A:Our company’s developed high-efficiency resin oil removal system is primarily composed of four core components: a constant-flow fiber oil separator, resin adsorption tower, outlet precision filter, and resin regeneration system. It adopts a programmable logic controller (PLC) combined with various precision online monitoring instruments to achieve real-time control and monitoring of power equipment and operating parameters such as temperature, pressure, and flow during operation.

Working Principle

Preliminary Separation in Constant-Flow Oil Separator

The oily solution first enters the constant-flow oil separator, which features a specially designed internal structure with coated coalescent materials. These materials exhibit oleophilic-hydrophobic properties and strong adsorption capacity for oil and organic impurities. Through the effects of baffle flow and coalescence, suspended oil and dispersed oil are enriched to form an oil film that floats upward, achieving preliminary high-efficiency separation.

Deep Purification in Resin Adsorption Tower

The pretreated solution is then pumped into the resin adsorption tower by a liquid-phase transfer pump. The tower is loaded with our independently developed special oil-removing resin, which has a macroporous structure and cross-linked network. With excellent specific surface area and pore structure, the resin efficiently utilizes its structural advantages to adsorb residual suspended and dissolved oil in the solution through van der Waals forces, further purifying the solution and removing organic matter. When the resin in the adsorption tower reaches saturation, it is switched to a standby tower, and the resin regeneration system is activated to desorb and regenerate the saturated resin, ensuring continuous operation without interruption.

Final Filtration

The purified solution finally flows through a filter equipped with high-performance composite material filter elements, achieving a filtration accuracy of up to 0.2 µm. This ensures interception and removal of any escaping fine particles, guaranteeing the excellent quality and purity of the final oil-removed product.