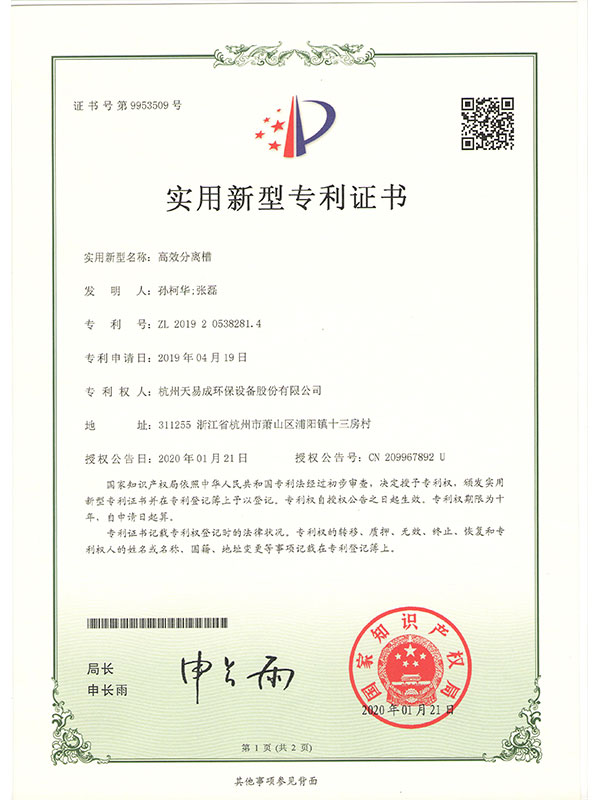

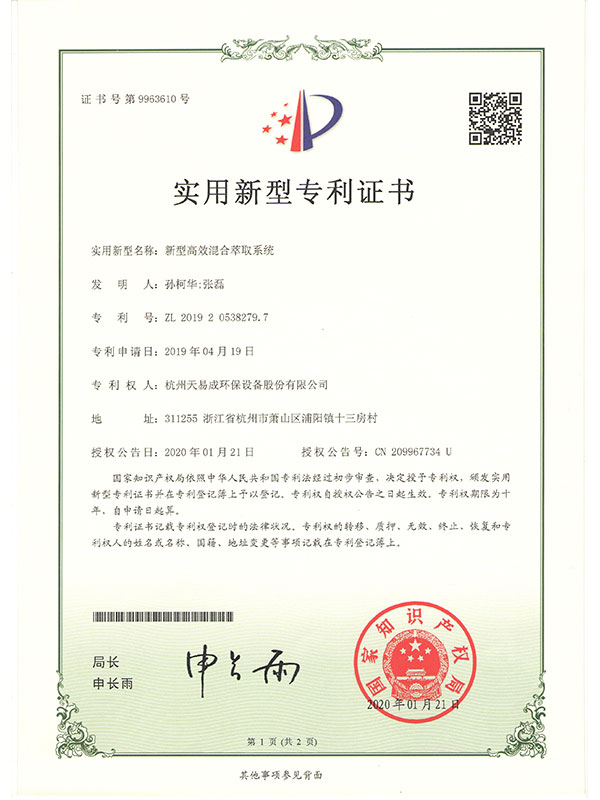

Hangzhou Tianyicheng New Energy Technology Co., Ltd. was established in 1997, It has 20 years of industry experience.Plant covering an area of 73,333 square meters. Tyic is equipped with a municipal R&D center, and has successfully passed the three-system certification and dual-carbon certification. In 2017, the company successfully listed on the New Third Board with the stock code 871858.

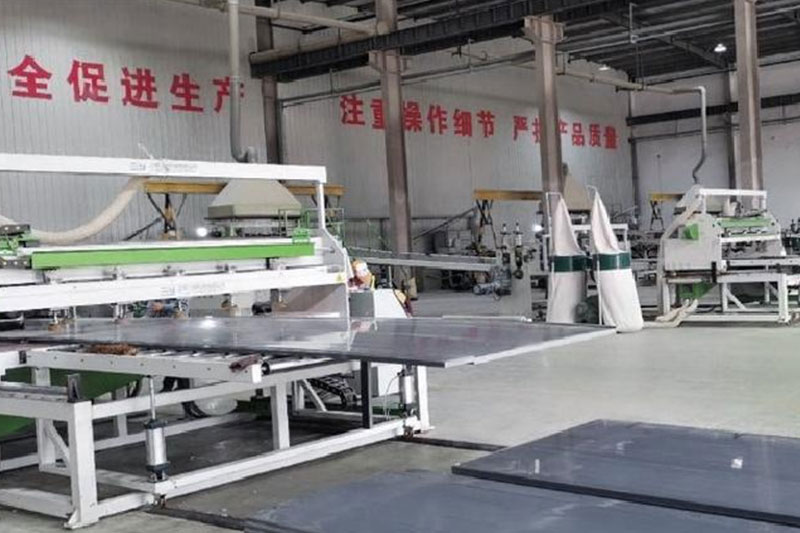

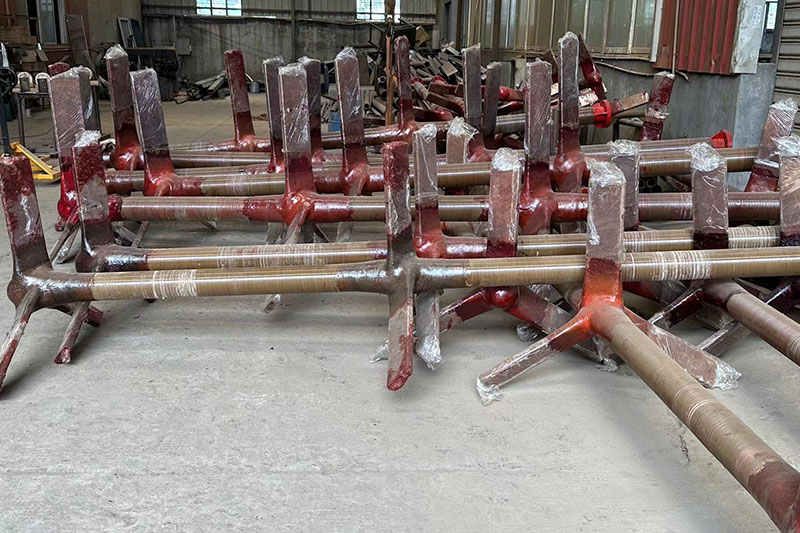

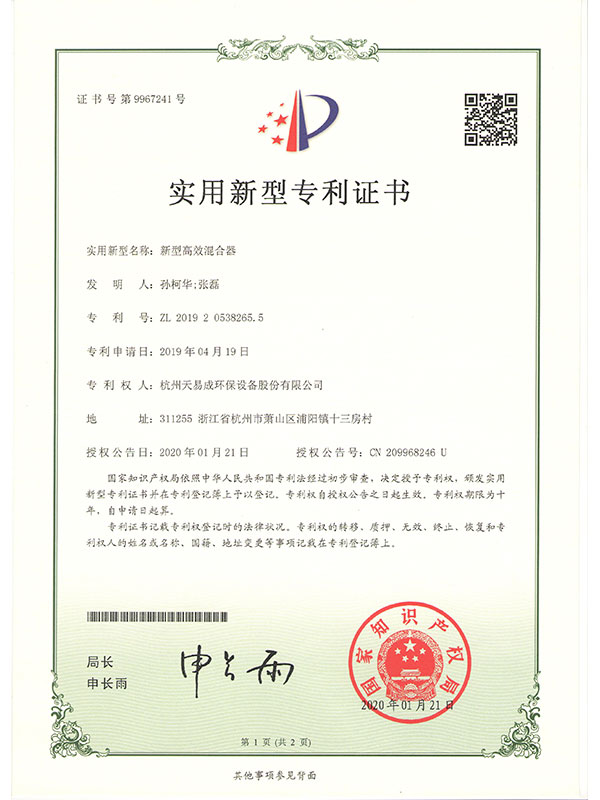

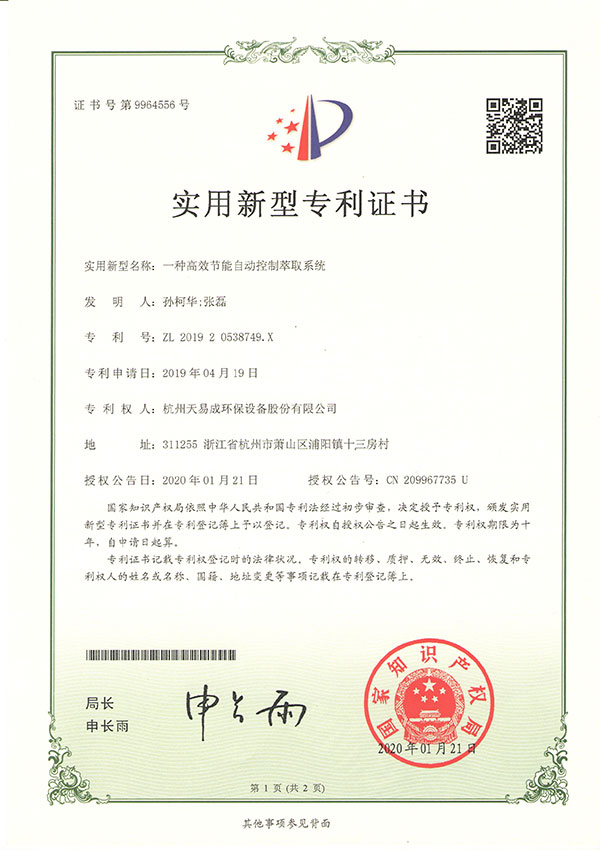

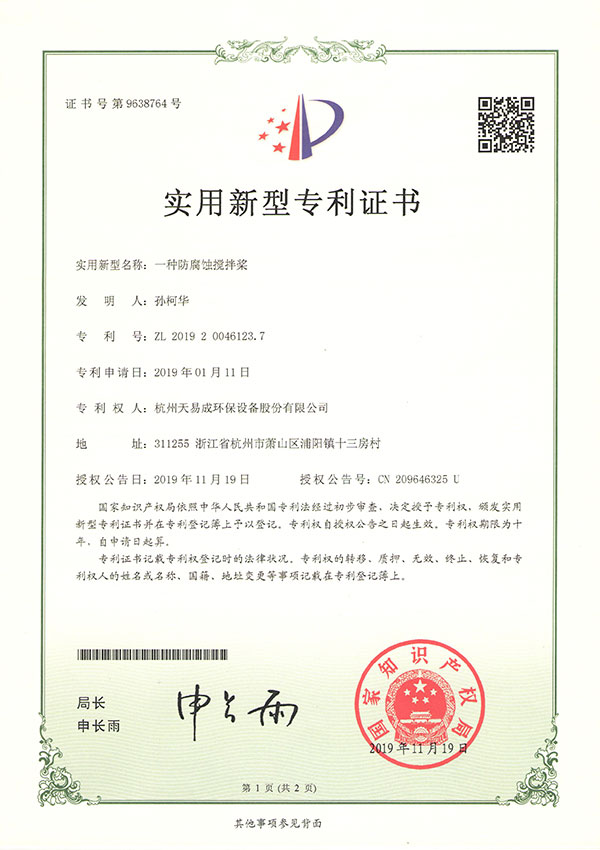

Tyic specializes in manufacturing chemical industry equipment such as anti-corrosion tank,Metallurgy equipment, and metal purification equipment, and provides environmental protection technology and processes for waste gas treatment. Currently, the company’s core business focuses on the automation equipment for extracting key materials of lithium-ion batteries through wet metallurgy,covering extraction equipment, leaching equipment, degreasing equipment, PPH winding tanks,mixing equipment, PVC sheets, etc.