Environment-friendly Extraction Cell

At present, the company is one of the largest manufacturers of extraction equipment in China, enjoying a high reputation both domestically and internationally. It can provide customers with total package services including design, manufacturing and installation. Currently, its clients include large enterprises and listed companies such as Tianen Co., Ltd., Luohuo Group, Hunan Bangpu, Grinmei, ECOPRO of South Korea, Ningbo Likelong, Wanhua Chemical, Ganfeng Lithium, Jinuyuan Sheng, and Kangpu Materials Technology. The number of projects it has served exceeds 100, and it is one of the participating units in the national standard “Process Design Specifications for Cobalt Smelting Factories”.It has a service life of over 10 years under harsh conditions and low maintenance costs.

- Obtained ISO9001 Certification

- Possess Core Patented Technologies

- Can Be Designed In Accordance With Overall Customer Requirements

- Multiple Patented Products With Structural Designs

- Excellent Sealing Performance And Comprehensive Exhaust Advantages

Environment-friendly Extraction Cell

Selection of Materials and Equipment

Use extruded all-plastic A boards or laminated all-plastic A boards for processing, with fixed dimensions, to reduce the proportion of welding; German imported semi-automatic extrusion welding gun, with uniform output, stable temperature control and good welding quality.

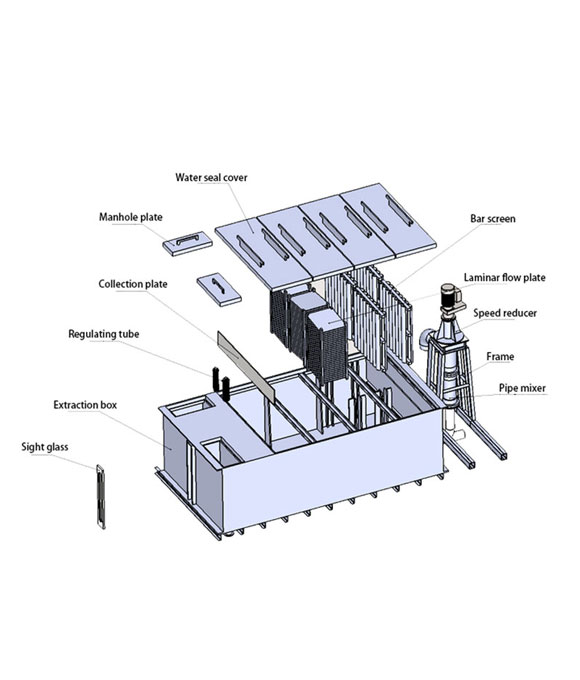

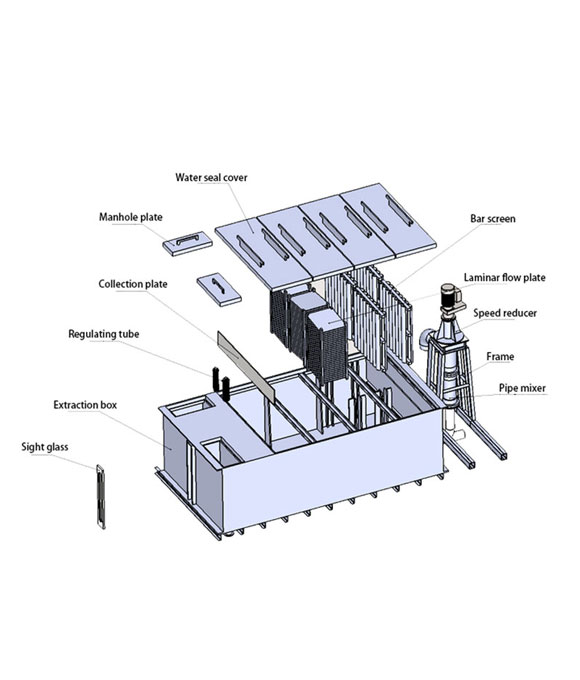

Design of the Mixing Settler

Adding a diversion cylinder to enhance the Mixing Chamber effect and suction force; optimizing the baffles to reduce centrifugal separation in the mixing chamber; labyrinth-type water-tight seal to reduce gas volatilization and improve operation.

Design of the Mixing Paddle

Low-speed operation can meet the requirements of mixing and suction, reducing gas dissolution. Adopting our company’s patented product – laminated glass steel one-piece molded agitator, it has excellent corrosion resistance, good dynamic balance and rigidity strength, and long service life, etc.

Clarification of the Design of the Tank Structure

From the conical inlet – the baffle – the annular grid – the IMI clarification partition – to the end gathering plate, the clarification rate is gradually increased and the two-phase entrainment is reduced. The thread adjustment controls the ratio of the two phases and the reflux flow rate. The operation is simple and the adjustment accuracy is high.

An external plexiglass sight glass is installed for convenient observation.

Check out our factory information to learn more about us.

Contact us as soon as possible to obtain real-time quotations.

Keep abreast of the latest information about TYIC.

Application fields

Rigid PVC Sheet

Excellent thermoformed plastics that can replace some stainless steel and other corrosion-resistant synthetic materials. It is widely used in chemical, petroleum, electroplating, water purification and treatment equipment, environmental protection equipment, mining, medicine, electronics, communications and decoration industries.

- Cost Performance:Compared with fiberglass, it has better temperature resistance,

anti-aging property, does not deform, is easy to process, and is more economical and cost-effective. - Corrosion Resistance:PVC has good corrosion resistance to corrosive liquids such as sulfuric acid, nitric acid, and strong alkalis. Therefore, it is widely used in chemical plants for storage, reaction, extraction, etc.

- Long Service Life:The PVC rigid extruded board has the characteristics of long service life and recyclability.

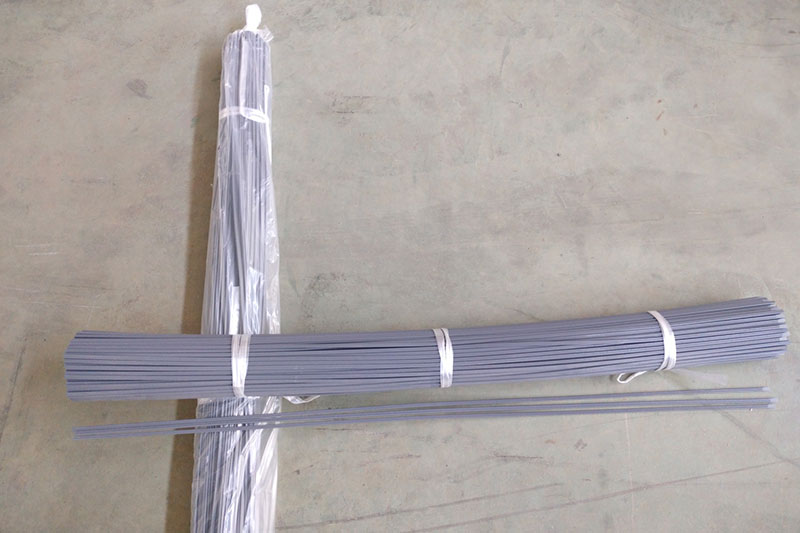

PVC Welding Rod

Suitable for the production of corresponding sheet materials and pipe products. Used for welding of various chemical equipment and general anti-corrosion machinery.

- Specifications: 2.0mm, 2.5mm, 2.8mm, 3.2mm.

- Varieties: Triangle, double-strand, triple-strand, circular.

- Length: 1m or customized according to customer requirements.

- Color: Light gray, white or customized according to customer requirements

- Packaging: Each bundle is packaged with 5 kilograms.

The product complies with the HGB2161-62 standard of the People’s Republic of China.

FAQ

A:Core Technologies:

Mixing Chamber: Equipped with a tubular mixer and mechanically sealed main shaft to prevent gas volatilization during the mixing process.

Clarification Chamber: Weld-sealed (PVC/PPH material) or integrally molded (FRP material), with water-sealed grille holes, manholes, and observation ports.

Liquid Level Monitoring: Side-mounted plexiglass or borosilicate glass sight glasses for direct observation, eliminating the need to open ports frequently.

Temperature Control: Plate heat exchangers maintain optimal extraction temperatures via heat exchange, reducing high-temperature organic gas emissions.

A:

Certifications and Compliance:

International standard:CE (EMC/LVD), RoHS (Hazardous Substances Free), ISO 14001 (Environmental Management System).

Chinese Standard:GB 16297 (Waste Gas Emission), HJ 2025 (Environmental Protection Technical Specifications).

A:Customization Options:

- Process Design: Tailored process based on raw materials and product requirements.

- Layout Optimization: Tank configuration designed to fit existing factory structures.

- Material Selection: Customized tank materials chosen to suit specific media.

- Technical Documentation: providing drawings include civil engineering requirements, P&ID diagrams, and piping connection layouts.