Provide technical support for clients in the industry in aspects such as the process design for organic waste gas treatment, the recycling technology for retired ternary power batteries(Ternary、LFP、LCO), the recycling process for nickel-cobalt intermediate products (MHP), the extraction and recycling process for rare and precious metals,.etc.

Turnkey Package Unit

Turnkey Project Services

· Selection and optimization of process routes

· Design of materials such as MB, PFD, P&ID, etc.

· Customized design of equipment structures

· Workshop layout planning and provision of civil engineering conditions

· electrical automation systems and pipeline tray designs

· Tank filling and commissioning supporting/basic training and management materials delivery management materials;

One-stop delivery from process route design to production commissioning and training.

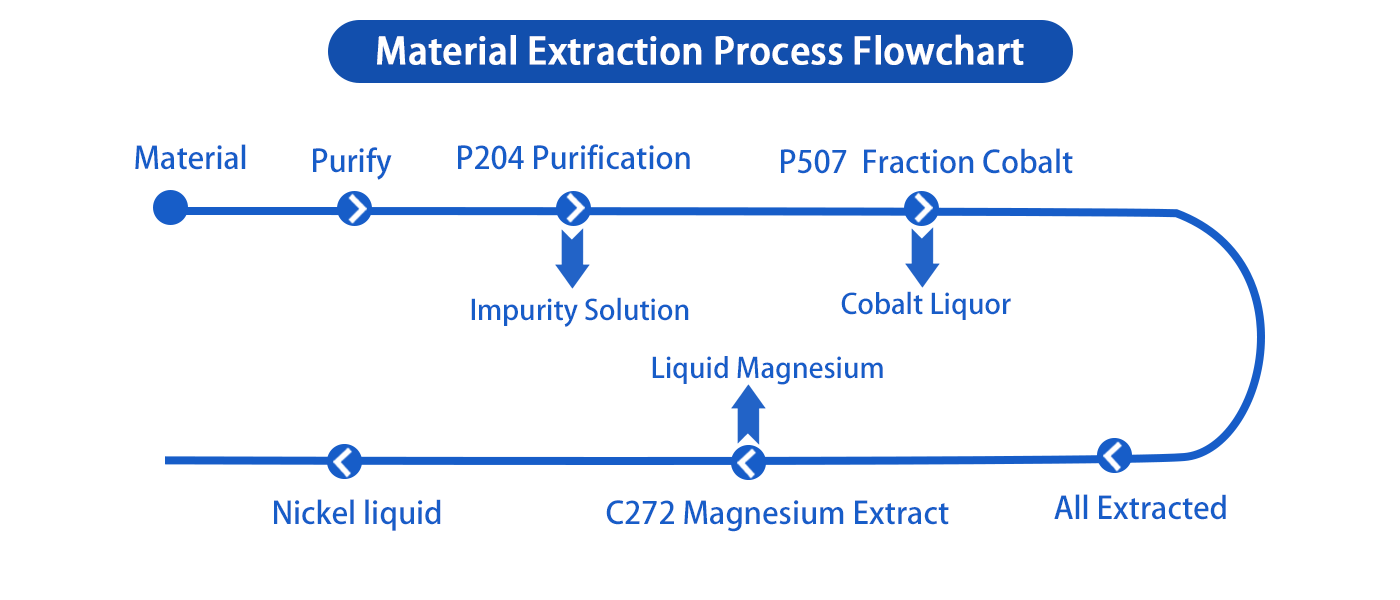

Material Extraction Process Flowchart

- Raw material undergoes P204 purification and P507-based cobalt fractionation, followed by impurity removal in solution.

- Cobalt liquor is processed with liquid magnesium and C272 extractant, culminating in full extraction of target components.

ANYTHING YOU COULDN’T FIND?

Advantages of Our Company

TYIC focuses on the global market. We have the following advantages:

- Customized Payment Cycle

- Low Cost

- Professional Technical Team

- Strict Quality Control.

- Fast Respond Or Enthusiasm.

SEND US AN EMAIL

Request a Quote

According to the customer’s requirements and the product characteristics, complete the planning and design of the entire set of leaching and extraction production line.